Product questions

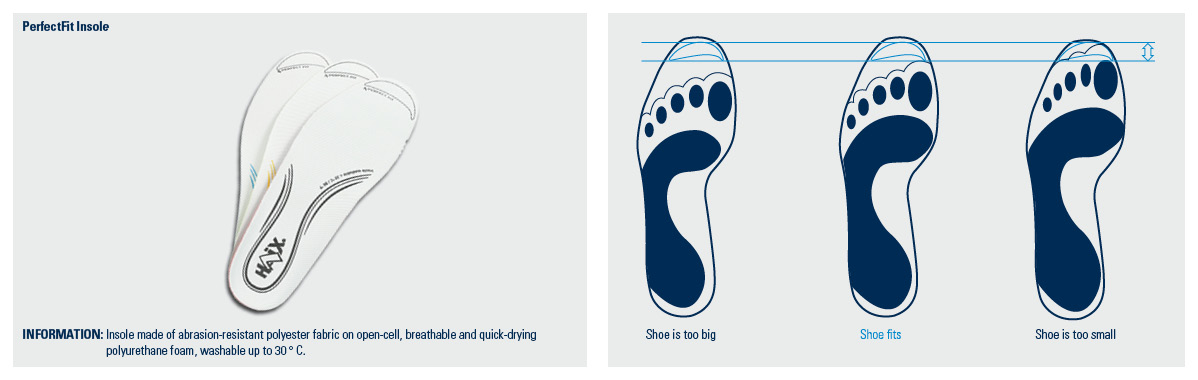

Please remove the insoles from your shoes and stand on them. It is important that your heels are flush with the insoles. The marked PerfectFit area will tell you whether the size you have chosen is suitable.

The Vario-Fit insoles are compatible with some of our shoes. Simply search for the right insoles for your shoe model at Accessoires and go to "Select size". If there are different types of insoles, you can choose between narrow, normal and wide foot. If your shoes are too narrow for you, the yellow insoles are ideal for the wide foot.

Please contact our customer support team for advice: [email protected] or +49 (0) 8751 / 8625 888. We produce on different lasts depending on the model - not all shoes are the same. We also offer free widening of up to 0.5 cm. Leather can be widened more generously than textile material. Shoes with a protective toe cap can only be widened behind the protective toe cap. Widened shoes cannot be exchanged.

Please remove the insoles from your shoes and stand on them. It is important that your heels are flush with the insoles. The marked PerfectFit area will tell you whether the size you have chosen is suitable.

Vario-Fit insoles are compatible with some of our shoes. Simply search for the right insoles for your shoe model at Accessoires and click on "Select size". If there are different types of insoles, you can choose between narrow, normal and wide foot. If your shoes are too big for you, the blue insoles are ideal for narrow feet.

Please contact our customer support team for advice: [email protected] or +49 (0) 8751 / 8625 888. We produce on different lasts depending on the model - not all shoes are the same.

Lacing systems may vary somewhat depending on the model.

Lacing instructions for one-off individual adjustment of the lace/zip fastener system

Lacing instructions for the new FIRE FLASH PRO laces

Lacing instructions for the new FIRE HERO, FIRE EAGLE laces

Lacing instructions for the new FIRE FLASH, FIRE FLASH GAMMA laces

Lacing instructions for the new SPECIAL FIGHTER laces

Lacing instructions for the new AIRPOWER XR1, AIRPOWER

| Product Name | Upper Material | Gore-Tex | Metal-Free |

|---|---|---|---|

| BLACK EAGLE Safety 40.1 low/mid | Textile | yes | yes |

| BLACK EAGLE Safety 41.1 low | Textile | no | yes |

| BLACK EAGLE Safety 50.1 low | Leather (1.8 - 2.0), without abrasion protection over the toe cap | yes | yes |

| BLACK EAGLE Safety 50 mid | Leather (1.8 - 2.0) | yes | yes |

| BLACK EAGLE Safety 50 high | Leather (1.8 - 2.0) | yes | no |

| BLACK EAGLE Safety 53 low/mid | Suede leather (2.0 - 2.2) | yes | yes |

| BLACK EAGLE Safety 54 low/mid | Leather (2.0 - 2.2) | yes | no |

| BLACK EAGLE Safety 56 low/mid | Leather (2.0 - 2.2) | no | no |

| BLACK EAGLE Safety 56 LL mid | Leather (2.0 - 2.2), with leather lining | No | no |

| BLACK EAGLE Safety Pro low/mid | Cut-resistant textile | yes | yes |

Our BLACK EAGLE Safety models offer you the highest comfort and safety. Except for the slightly narrower women's models (marked with 'Ws'), all models are produced on the same last and have consistent sizing. Additionally, they are certified to safety class S3 and are suitable for orthopedic insoles, ensuring reliable protection in demanding work environments.

BLACK EAGLE Athletic & BLACK EAGLE Tactical

Our BLACK EAGLE Athletic and Tactical models differ only in the materials used for the upper:

GTX: Gore-Tex (waterproof)

T: not waterproof

N: Nubuck leather

V: Suede leather

The rest is made of textile or smooth leather. All models are certified according to occupational footwear standards and are suitable for orthopedic insoles.

The BLACK EAGLE Adventure models are identical in construction to our BLACK EAGLE Athletic and Tactical series. The upper material is textile, and the women's models (marked with 'Ws') are narrower. The main difference: these models do not meet any professional standards and are considered purely leisure shoes.

HAIX shoes are 100% Made in Europe. For us, this is not just lip service, but lived practice. When it says "Made in Europe" on a HAIX shoe, we assure you that it was made exclusively at our production sites in Mainburg and Mala Subotica, Croatia. Both plants are among the most modern shoe manufacturing facilities in the world.

By the way: "Made in Europe" is not only a promise of quality for us, but also stands for good working conditions, equal opportunities, sustainability and corporate responsibility.

Outdoor

The reason for this is that very large sizes are only infrequently requested by customers. This means that production costs are higher than for standard sizes. Production processes also need to be specially adjusted, for example, and material use is greater. Nevertheless, we wish to be able to continue to provide this particular service to our customers. We are, therefore, compelled to charge an oversize supplement for shoes which do not correspond to the usual sizes.

Instructions for custom-made orthopedic insoles with the HAIX® CO System

Are you looking for a specific model and can't find it in our webshop? It might be a special or discontinued model.

Would you like more information about this shoe? Please contact us:

Labeling of the categories of safety footwear EN ISO 20345

SB: protective toe cap + slip resistance basic requirement

S1: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area

S2: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material

S3: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + metal penetration protection

S3L: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + non-metallic penetration protection type PL

S3S: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + non-metallic penetration protection type PS

S6: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe

S7: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + metal penetration protection

S7L: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + non-metallic penetration protection type PL

S7S: protective toe cap + slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + non-metallic penetration protection type PS

Labeling of the categories of occupational footwear EN ISO 20347

OB: slip resistance basic requirement

O1: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area

O2: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material

O3: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + metal penetration protection

O3L: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + non-metallic penetration protection type PL

O3S: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + non-metallic penetration protection type PS

O6: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe

O7: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + metal penetration protection

O7L: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + non-metallic penetration protection type PL

O7S: slip resistance basic requirement + closed heel area + antistatic + energy absorption in the heel area + water-repellent upper material + waterproofness of the entire shoe + non-metallic penetration protection type PS

Classification of fire brigade footwear in accordance with the CE 0197 EN15090 standard

Code 1: Shoes made of leather or other materials, except footwear made entirely of rubber or polymers

Code 2: Footwear made entirely of rubber or polymers

Types of brigade footwear in accordance with the EN 15090 standard

Type 1: Suitable for general technical deployments (e.g. Type 1, HI1) and fire fighting outdoors only (e.g. Type 1 HI2; Type 1 HI3)

Type 2: Heavy duty basic protection models, suitable for internal fire fighting and combating other fires of all sorts; standard fire brigade boots (e.g. Type 2 HI2; Type 2 HI3)

Type 3: Special protective version, suitable for deployment in exceptional risk situations such as those involving hazardous materials; also suitable for all sorts of fire fighting (e.g. Type 3 HI2; Type 3 HI3)

Type and protective function of fire brigade footwear is stated in the bottom left-hand corner of the pictogram (fire fighter), e.g. F2A, whereby the following applies:

F Fulfils all requirements under the standard

2 Type 2

A Fulfilment of antistatic requirements

Meaning of the labelling symbols

HI1: Heat insulation performance level of the sole design at 150°C / 30 minutes

HI3: Heat insulation performance level of the sole design at 250°C / 40 minutes

The HAIX Climber and the HAIX Protector Alpin are able to accommodate crampons.

A shoe is considered antistatic if the measured resistance falls within the range of 100 kiloohms (10^5 ohms) to one gigaohm (10^9 ohms). Antistatic shoes must be used according to standards to reduce electrostatic charge and ensure its dissipation. This is necessary when the risk of electric shock from electrical devices or live parts cannot be ruled out, or when there is a risk of igniting flammable substances or vapors due to sparks. The goal is to protect the wearer of the safety shoes (and also people in the vicinity) from hazards associated with electrical charge.

For ESD-capable shoes, the lower limit of resistance is also 100 kiloohms, but the upper limit is 100 megaohms (1 x 10^8 ohms). This means that an ESD-capable shoe is always antistatic as well. However, an antistatic shoe is not automatically ESD-capable. ESD-capable shoes protect not only the wearer and those nearby but also safeguard workpieces and equipment through controlled dissipation.

Nubuck leather is sanded smooth leather, while suede is made by splitting and then roughening the leather. Both types of suede leather appear velvety in texture. Suede is particularly known for being very durable and easy to care for.

The key difference between these two models is water resistance. Our CONNEXIS Go models are equipped with Gore-Tex, making them waterproof, whereas the CONNEXIS Air models are not waterproof.

Our CONNEXIS Force Air stands out for its high-quality and lightweight nubuck leather, making it the ideal leisure shoe for warm days.

Here you will find an overview of our common abbreviations:

| Abkürzung | Bedeutung |

|---|---|

| GTX | Gore-Tex |

| Ws | Women's models (smaller sizes, narrower lasts) |

| T | Textile lining |

| LTR | Leather upper material |

| C | CrafTex upper material |

| LL | Leather lining |

| V | Suede leather |

| N | Nubuck leather |

| WTR | Winter |